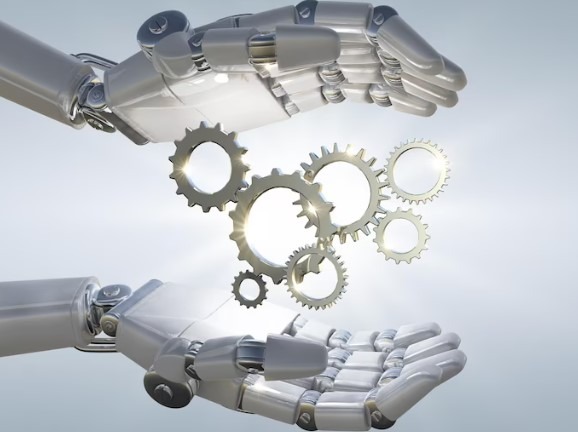

In the manufacturing sector, gear-cutting tools are essential because they make it possible to produce high-quality gear for use in various applications. These tools are made to precisely and accurately shape, mold, and produce gears. In this article, we’ll examine the significance of gear hob cutters manufacturers and how their creative approaches help to produce gears effectively.

The Importance of Gear-Cutting Equipment

In sectors like automotive, aerospace, and equipment where the need for gears is great, gear-cutting tools are essential. These devices make it possible to design gears with various diameters, tooth profiles, and requirements. Manufacturers can accomplish the necessary gear properties, such as tooth profile accuracy, pitch, and surface finish, by adopting cutting-edge technology.

- Engineering with Precision for Optimal Results

Manufacturers of gear-cutting tools use precise technical methods to guarantee the highest levels of quality. Cutting tools are produced using highly precise production techniques, including CNC machining and grinding. As a result, the durability, vibration, and noise of the gears are improved. The durability and general performance of machinery and equipment are both influenced by the capacity to create gears with such precision.

- Customized Answers for a Wide Field of Uses

Tools for cutting gear Manufacturers provide tailored solutions in response to the various needs of their clients. They work together with producers from many industries to provide cutting instruments that adhere to strict specifications. These manufacturers can offer specialized solutions to improve the performance of gears for industrial machines, aircraft engines, or automobile transmissions.

- Efficiencies Driving Innovations

Technology is always evolving, which has completely changed the gear-cutting tool production sector. Manufacturers consistently spend money on R&D to increase the effectiveness and performance of their instruments. That involves utilizing cutting-edge coatings, materials, and geometries to create tools with faster cutting rates, longer tool lives, and less downtime for tool replacements. For manufacturers, these advancements boost productivity and save costs.

The manufacturers’ technical teams possess deep knowledge and expertise in gear-cutting processes, enabling them to offer valuable insights and solutions to optimize gear production.

- Sustainability in Manufacturing

Along with accuracy and efficiency, gear cutting tool manufacturers are increasingly incorporating sustainable production methods into their operations. They are employing eco-friendly practises since they recognise how crucial it is to lessen their adverse effects on the environment.

Conclusion:

Gear hob cutters play a critical role in the manufacturing industry by providing precision solutions for gear production. Their focus on innovation, customization, and quality assurance ensures that manufacturers can rely on their tools to achieve optimal gear performance. As technology continues to advance, we can expect further enhancements in gear-cutting tools, leading to even more efficient and precise gear manufacturing processes.

Read Also: What is a Executive Engineer

Leave a Reply